Centuries ago, the Greeks could not have known that their word “polymeres”, meaning “having many parts”, would today serve as the name for a whole class of materials. A polymer can be defined as a substance which has a molecular structure built up from a large number of similar units (called monomers) bonded together.

Let’s not forget that Nature invented polymers first – proteins, carbohydrates, your hair, fingernails, even your DNA is a polymer. Man-made polymers came along much later but today are ubiquitous and play an essential role in modern life.

There are currently about 300 million tonnes of polymers made annually, representing ~6% of oil and gas consumption globally. They fall into two broad categories – thermosets and thermoplastics. Thermosets are polymers which typically start as viscous liquids which when subjected to heat or pressure harden to form a solid which cannot be melted again. Araldite® glue is an example. Thermoplastics, the subject of this article, soften and melt to be shaped when heated and then harden once cooled. They can be remelted and reshaped.

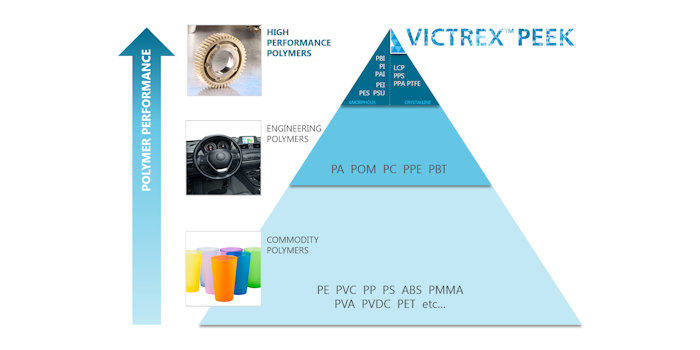

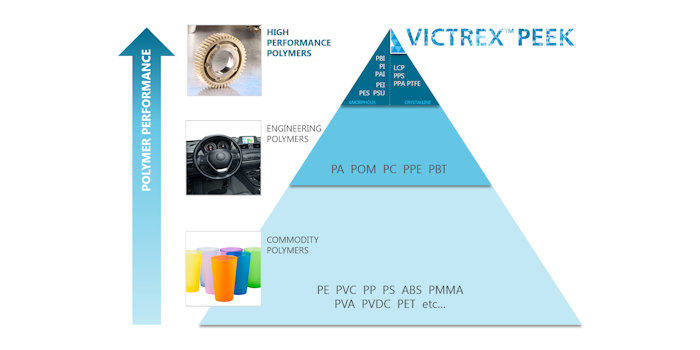

The pyramid of polymers

One of the easiest ways to understand this complex topic is to view polymers as a pyramid. This identifies three major categories of polymers:

- Commodity polymers

- Engineering polymers

- High-performance polymers

Commodity polymers

Commodity polymers such as polypropylene (PP) and polyethylene (PE) are at the base of the pyramid. They are readily available in large quantities and have a reasonable performance for the applications in which they are used. PE, for example, is commonly used to make high-volume items such as plastic bags and packaging materials, applications where high temperature or extreme strength is not a critical factor.

Polyvinyl chloride (PVC), meanwhile, is for example widely used in the construction industry and comes in two forms, rigid and flexible, with the rigid version used in window frames, guttering and piping and the flexible version commonly used for the insulation of electrical cabling. The raw materials for commodity polymers are usually obtained from oil and petrochemical derivatives, and typically they are inexpensive to produce. The main raw material for PVC however is salt.

Engineering polymers

In contrast, engineering plastics are a distinct step up from commodity polymers and offer a superior range of properties, particularly in mechanical and thermal performance – but with superior performance comes a higher price. For example, the polyamide family (Nylons) has a wide range of applications, from textiles for clothing to food and beverage containers, and in engineering applications like domestic appliances and automotive components.