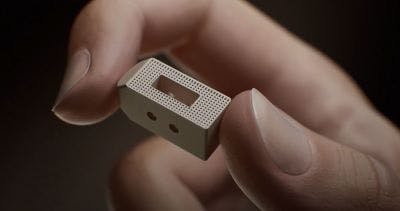

Unlocking the possibilities for 3D printing PEEK structures

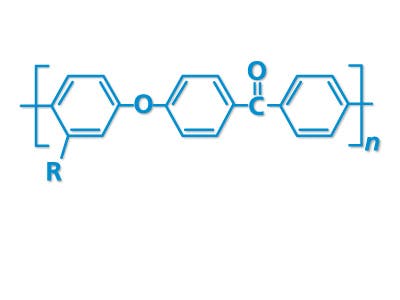

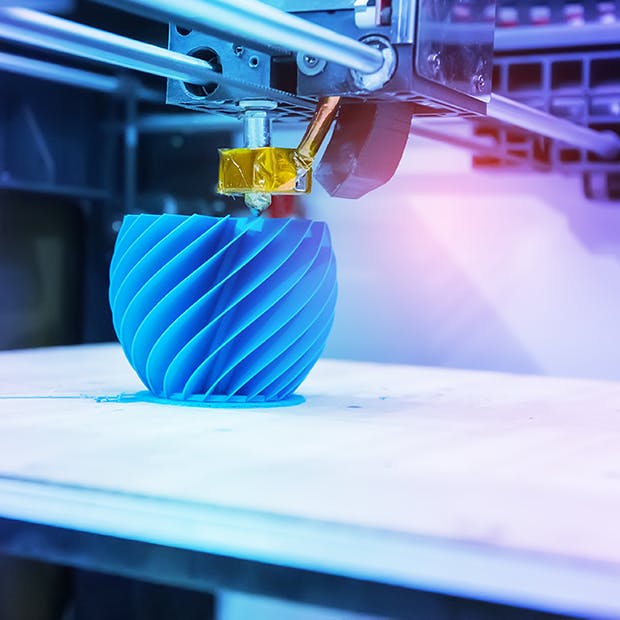

Invibio launches PEEK-OPTIMA™ AM filament, making available the trusted implantable-grade polymer in a form specifically developed for Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF) additive manufacturing processes.

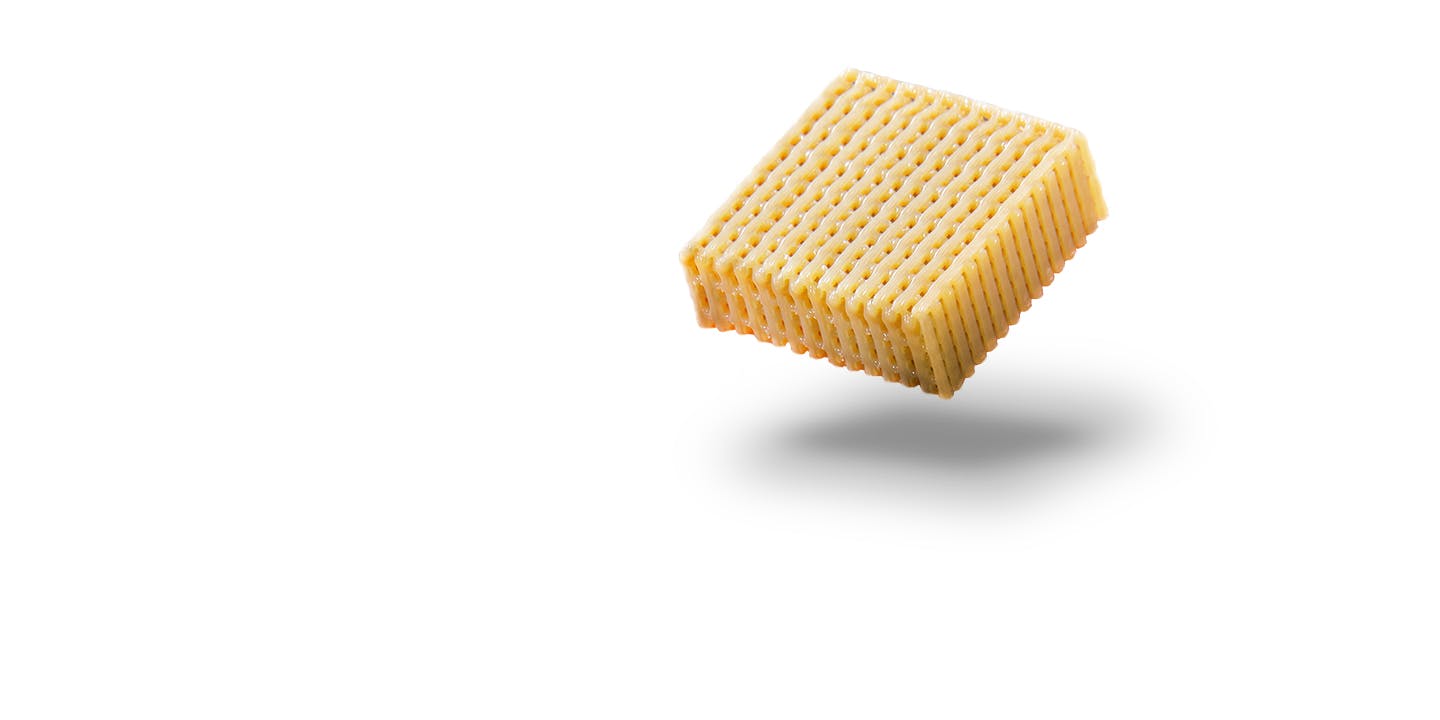

Collaboration with Bond3D to develop implants of the future